8/18/2007 Port Jefferson - Photo/Archive: John Volpi

10/10/2003 Smithtown - Photo/Archive: John Volpi

Ballast train at Willets Point 11/21/2013 Photo/Archive: Kevin Wong

LI 6100-6162 13 rib series LI Ballast Hoppers #6112 at North Haven, CT

6/23/96

Photo: Richard Louderback, Archive: Dave Keller

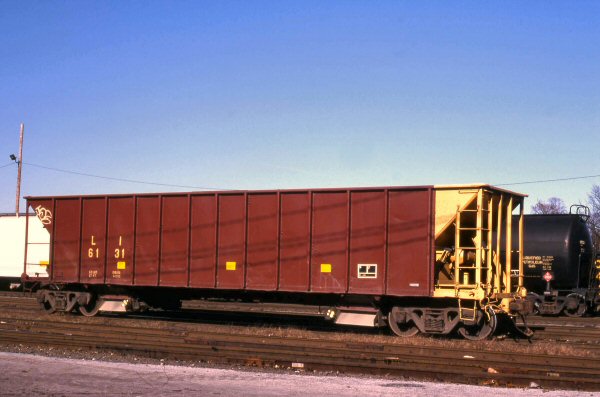

LIRR Ballast Hopper #6131 at Fresh Pond Junction – Fresh Pond, NY – 11/11/99

Photo: Al Tillotson, Archive: Dave Keller

LI 6160-6162 15 rib series LI Ballast Hoppers #6161 extended side at LI City, NY 10/21/07

Photo: John McCluskey

Note: Is this a rebuild of the LI #6160-6162 last three cars with additional capacity and ribs added?

LI 100015-100034 11 ribs 3 center ribs close together series LI Ballast Hoppers #100034 at Port Jefferson, NY 9/21/2003 Photo: John Volpi

West Yard Port Jefferson 9-23-03

LI #6122 Port Jefferson 09/01

LI #6137 Smithtown 10/10/03

LI #6147 Farmingdale 09/20/03

LI #6151 Smithtown 01/11/07

LI #6160 Port Jefferson 09/03

Inside Brace 10/06

Truck 10/18/06 Smithtown

Lube Plate 0/06 Smithtown

LI #100028 Smithtown 10/03

LI #100034 Port Jefferson 09/21/03

LI #6137 Dump Controls Smithtown 10/2001

LI #6110 ballast hopper - Jamaica 8/03/2018 Photo/Archive: Tim Darnell

LI #6105 ballast hopper - Jamaica 8/03/2018

Photo/Archive: Tim Darnell

Note: Hopper at right is series

LI 100015-100034 11 ribs 3 center ribs close together series:

Hopper is #10001xx.

All photos this section: John Volpi unless noted.

Ballast train Main Line Third Track Project at Mineola - 7/11/2021 Photo/Archive: Bill Mangahas

These ballast hopper fleets have automated discharge capabilities that allow for specific unloading flows to be remotely initiated, avoiding the need for a crew member to walk beside the car during unloading. The solar panels used to keep the batteries for those systems charged.

Herzog hoppers at Mineola - 7/11/2021

Photo/Archive: John Ciesla

You can see the single operator

using pushbuttons on the car side to control the ballast flow. It appears to

me that he is dropping ballast between the rails where he is watching and to

the outside the rails

ehind himself.

The solar panels that recharge the batteries allowing this control are

visible at the ends of the hoppers. These hoppers have electrically actuated

hydraulic controls on all chutes that can be controlled either from the side

of the hopper or using a remote control.

That remote control capability does mean that Herzog can preplan ballast

drops with railroads and drop controlled amounts of ballast in confined

spaces using GPS and inertial navigation to avoid the need to have someone

walk along side the train to drop ballast in tunnels and other dangerous

spaces.

New LIRR ballast hopper cars numbered in the 617x or 616x series and there are at least eight of them. Built by Ebenezer Rail Car Service in Buffalo, NY. A load capacity of 225,700 lbs./2,680 cubic feet with a Loram control system in a locked box at one end.

Photo/Archive: Barry Johnson

LI #6164 MW - 7/01/2025 Photo/Archive: Chris Kokonis

Herzog solar powered ballast cars

Photo/Archive: Herzog Corp.

LI #6175 MW - 7/01/2025 Photo/Archive: Chris Kokonis